#21 Surface protection treatments, emissions & regulations

Contents

- 1. Introduction: the protective surface treatments

- 2. Intended use & regulations

- 3. Ceramic surfaces & food

- 4. Tests & verifications

- 5. Producers's role

- 6. Surface treatments: rules to be considered:

- a) Tests on treated surfaces

- b) Dyers

1. Introduction: protective surface treatments

Polished and lapped ceramic tiles usually require specific protection treatments to clog the open pores that may emerge on the surface after the lapping/polishing process. A process, that is fundamental in avoiding or, at least, reducing possible chemical or dirty attacks.

The target of surface treatments is to protect the surface, improving its performance without changing the basicfeatures of the tile. More generally, tiles (treated or not treated) must comply with regulations and market’s targetthat can clearly change according to clients and the ceramic’s intended use.

2. Intended uses & regulations

For example, ceramic tiles used in supermarkets or airports (high traffic areas) must meet targets that are different from those required by a private house or a pub. In this regard, there are official and internal rules (the latter set by customers/ceramic producers) that define the characteristics that the surface must have. In this respect, in recent years new regulations have appeared on the market due to the increasingly different intended uses of the ceramic material. In fact, the ever-increasing ceramic dimensions together with the surprising decoration possibilities promoted by the digital technology opened the ceramic material to new application areas and firstly to furniture and interior: tables, worktops, countertops, etc. etc. In many cases, these new scenarios call into question some new guidelines that define the technical features of ceramics in case of food contact.

3. Ceramic surfaces & foods

In this perspective, words like SANITIZATION and CLEANLINESS that already belong to ceramics, have today new connotations that should not be taken for granted. Especially when the material is not used for floors or walls. Today, despite their outstanding and very high hygienic performances, ceramic surfaces must be even more carefully checked to avoid and prevent possible toxic releases that may affect, by contact, the food we eat, resultingin harmful effect on humans. This is a topic that, for obvious reasons, ceramic producers have never addressed but that today, despite the extraordinary hygienic performances of ceramics, should be in agenda. In fact, however the toxic releases can be very low and not harmful, it is important to rise the bar of quality and performance to meet the regulations that are today increasingly demanding. This is the reason why ceramic producers and chemical companies that supply products for surface treatments must be aware and careful about regulations, providing the surface with the proper features.

4. Tests & verifications

Given that the surface must not release any kind of toxic compounds for food and therefore for humans, tiles must undergo to lab tests by using chemical agents that reproduce and replicate the acidity and alkalinity of foods, allowing you to check over a period (that can range from a few hours to a few days) the possible release of toxic and harmful elements. Without being too specific, we can say that, in general, the current regulations provide for limits that cannot be crossed. Limits that are measured in ppm (parts per millions) and that can change depending on the context. They also may concern some specific substances or the entire amounts of released compounds. This means, for example, that some entities can require specific limits for Cadmium or Selenium, setting at the same time other limits that check the releases of all elements (and their possible compounds).

5. Producers' role

What are the elements that can be found on the ceramic surface and that should be previously checked by producers to avoid possible releases? Let’s try to make a list, considering the most important elements:

- Grits and frits composition

- Composition of all chemicals used for grit application

- Composition of all chemicals used along the entire production process

- Composition of the product used for surface protecion treatments

It is also important to underline that this approach makes sense when materials and compounds that must be checked do not undergo to processes, such as the firing cycle, that can transform their features. In ceramic, these controls are not very significant, since tiles – before entering the market – are subjected inside the kilns to very high temperature that almost completely change the initial composition of the material, including their possible interaction with foods. However, the method of analysis is useful, and it remains valid with respect to surface treatments, that, in fact, take place only after firing, therefore without undergoing to any thermal transformation (after application). This means that the formulation of the product must be carefully developed not only in terms of protection from chemical and stains attacks but also in terms of possible emissions that the protective product discharged on the ceramic surface may promote.

Before addressing surface treatments, let’s make a brief reference to another important topic: the raw materials the make up the raw ceramic body and more specifically the elements that form the tile’s surface that is more exposed to contacts. In general, the ceramic glass, regardless its chemical composition that can change depending on the glass, must be the most resistant as possible to chemical agents (acids and alkaline), to avoid solubilizations of those elements on the surface that, even if they are not potentially toxic, can be a problem in case of excessive or non-standard amounts

What does that mean?

The ceramic glass, as we know, is mostly made up of elements that come from:

- Silica

- Aluminum

- Calcium

- Magnesium

- Lithium

- Sodium

- Potassium

- Etc.

All these elements, each of them in different amounts, are potentially present on the tile’s surface and they could be released during the tests, when simulating an acid or alkaline attack.

According to producers’ needs or to regulations, the type and total amount of the released compounds may sometimes exceed. The presence of the overmentioned elements is very unusual but, in very unfortunate cases this scenario may appear. This reason is enough to carefully check to prevent extreme situations.

6. Surface treatments: rules to be considered

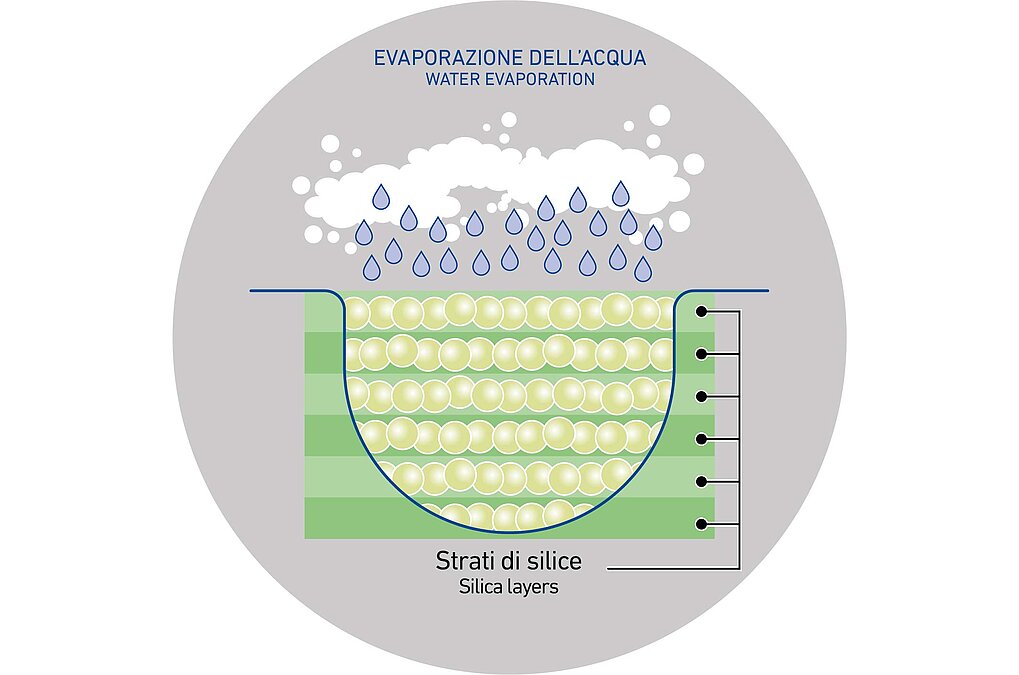

The protective product that is discharged on the ceramic surface by the brushes of the application machine, even if it does not undergo to any thermal alteration, remains (from a chemical point of view) almost unchanged after application. But that’s not all. COLLOIDAL SILICA that are the basis of almost all products for surface protection, once they have lost their liquid part (the solvent) and after they have bonded to the ceramic surface, thus filling the open porosity, produce seals of amorphous silica (not crystalline). The water evaporates and what remains is the glass that binds to the ceramic surface.

This is a very important detail, considering that amorphous silica is NOT TOXIC. In fact, since it is a polymeric glass in aqueous solvent, it does not spread any VOC, neither during nor afterapplication. This could happen, instead, when using different chemicals (both water and solvent-based). It is finally comforting to know that the treated surface, in most cases, is suitable for food contact.

TESTS ON TREATED SURFACES

The tests on colloidal silica used within protective products usually show an outstanding resistance to acid attack and a weak (if not very weak) resistance to alkaline attack.

What does that mean?

It means that – in the solution used to simulate the alkaline attack – we may find the presence of solubilized silica (that is silica released by the ceramic surface) that, even if is not toxic or harmful for humans, it could affect the treatment efficacy. This is very challenging for R&D Labs, since they must work (and they are already doing it) on solutions able to develop a higher resistance to alkaline attack. The goal can be reached by adding to the formula polymers, resins and/or wax that can support (or even replace) the good action of colloidal silica. It is therefore important to previously test these elements or substances, carefully checking possible release after application, that is after the REACTION that develops on the tile’s surface. This also means to simulate what happens after the protective product’s application, verifying the stability and durability of the product. One of the most important targets is to avoid, even with this kind of chemicals, the presence of VOC: they can be present during application, but they must disappear after the process. It is also fundamental to prevent, even with these products, the persistence over time of oligomers or monomers thatmay be harmful, by promoting instead the use of non-toxic self-crosslinking polymers whose non-toxicity must be present both before and after the reaction that takes place on the surface.

Of course, this approach is important not only for companies that provide chemicals but also for all glaze and color producers that should study and develop glass that do not produce any harmful emission after firing.

DYERS

Products for surface treatments are usually marked by a neutral color that do not compromise the aesthetic features of the surface. However, to reach better and higher performing results, some specific dyers that match the general color of the tile can be added in solution.

In this regard, the dyer’s chemical composition should not be underestimated since its presence within the product may release substances – after treatment – in case of superficial contacts with acid or alkaline solutions. Sometimes, the dyer can be released by the surface even in case of aqueous solutions and this exactly the reason why a great attention during the products formulation is essential. Dyers must be chemically and physically bound inside the product (the treatment) so to be more resistance to external agents and release tests. This is one of the goals of the ceramic sector.

Back to How To